Metal spinning is a metalworking process that uses roller force to form a flat sheet of metal into a desired shape. The process is performed by pressing a roller into the metal sheet while it is spinning on a mandrel. The metal flows and conforms to the shape of the mandrel, creating a shape that can be utilized across numerous applications.

Metal spinning has been used for centuries to create a variety of objects, including bowls, domes, cones, and cylinders. It is a versatile process that can be used to produce parts from a variety of metals, including steel, aluminum, copper, and brass. Metal spinning also refines the structure of the metal to improve hardness and tensile strength. Without the weak points created by seams, spun parts often provide superior durability and strength than other manufacturing processes.

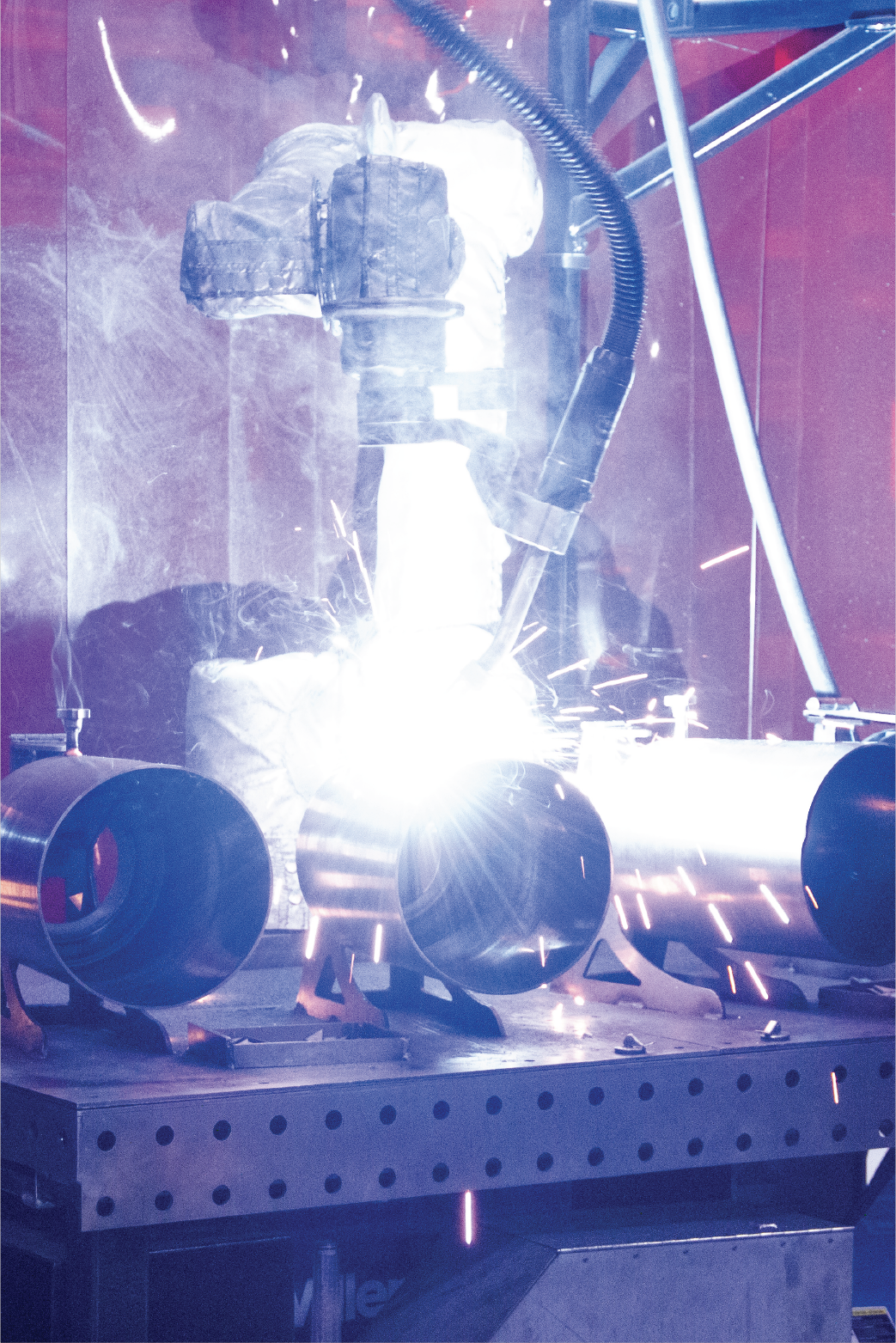

At KRYTON, our robotics systems enhance our productivity and our CNC equipment enable our team to spin metal over pre-designed shapes, forming products that meet your exact dimensions. The metal adheres to the contours of the engineered shape, creating a solid part whose quality you can trust. Because we’ve engineered both the form and the process for your business specifications, we can repeat this work again and again to ensure each new part is as stable and trustworthy as the last.

Why choose KRYTON?

Our on-site engineering team has seen and cut nearly everything in metal fabrication — including nearly 10,000 unique parts. No matter what your project requires, our team of engineers can put together a custom design and then work closely with production to ensure your metal is cut and shaped to the most demanding specs. Through every step of the engineering and design process, we’ll work directly with you so you can review what’s happening and make any adjustments as needed. We take our craft seriously and our customer service team is standing by as your guide from creation to on-time delivery.

Design

Experience the forefront of metal innovation with KRYTON Metals, our company is renowned for its exceptional design capabilities. Our team pushes the boundaries of metal engineering, using advanced technology and expertise to craft precise components for a wide range of industries. Our engineers utilize top software including SolidWorks, SolidCam, Cenit, and Faro for precise results. From concept to creation, we offer tailored solutions to elevate your products' performance and functionality.

Engineering

Our advanced engineering capabilities enable us to provide innovative solutions for a wide range of industries. We specialize in the design and manufacture of custom metal components, from prototypes to production parts. Our team of experienced engineers and technicians use the latest technology to ensure the highest quality parts and products. With unmatched innovation and a commitment to quality, we redefine possibilities for a stronger, greener future.

Cutting

With over 30 years of experience, our cutting-edge machinery and expertise enables us to provide precision cutting services for a variety of metals. From small parts to large complex components, KRYTON Metals can handle it all with speed and accuracy. With our superior quality and competitive pricing, KRYTON Metals is the go-to source for all your metal cutting needs.

Spinning

KRYTON Metals is a leader in metal spinning technology. Our experienced staff and state-of-the-art equipment allow us to provide superior quality metal spinning services for a variety of applications. We specialize in a wide range of metals and can create complex shapes with precision accuracy. With our commitment to excellence and customer satisfaction, we'll ensure your parts are spun and cut to exact specs to get the highest quality product with the best turnaround time possible.

Explore Additional Resources

Laser Cutting

Laser Cutting

Laser cutting lets you encourage innovation, optimize spending, and minimize environmental impacts. Discover the benefits and learn how to take advantage.

Metal Fabrication Capabilities

Metal Fabrication Capabilities

Metal fabrication supports sustainable design and manufacturing with customizable techniques and a choice of materials and processes to fit eco-friendly standards.

Metal Tolerancing

Metal Tolerancing

Sheet metal tolerances help manufacturers align components and ensure optimal performance. Tolerancing is crucial for most industries. Learn why precision matters for sheet metal fabrication.

Metal Tooling

Metal Tooling

Metal tooling creates, modifies, or repairs metal parts, components, and assemblies. Explore different metal tooling techniques and applications to develop a comprehensive plan.

Spinning vs Stamping

Spinning vs Stamping

Modern metal fabrication offers multiple options for manufacturers. Evaluate the benefits of metal stamping and forming to determine the best approach for different projects.

Spinning vs Rolling

Spinning vs Rolling

How do metal rolling and metal spinning compare? Discover the differences, pros, cons, and applications to make an informed decision.

Featured Ebook