Comprehensive Tooling & Welding

Streamline your production with our all-inclusive tooling and machining capabilities, from initial cuts to final touches.

Capabilities

Elevate your metal fabrication projects with expert engineering, precise welding, and comprehensive finishing and assembly.

Request a QuoteLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididtat non proident.

Made in the USA since 1981.

From initial engineering to final assembly, our comprehensive services include welding, finishing, metal polishing, and more.

Each project has unique demands, along with a specific timetable and budget. Our value-add services are here to meet your exact requirements.

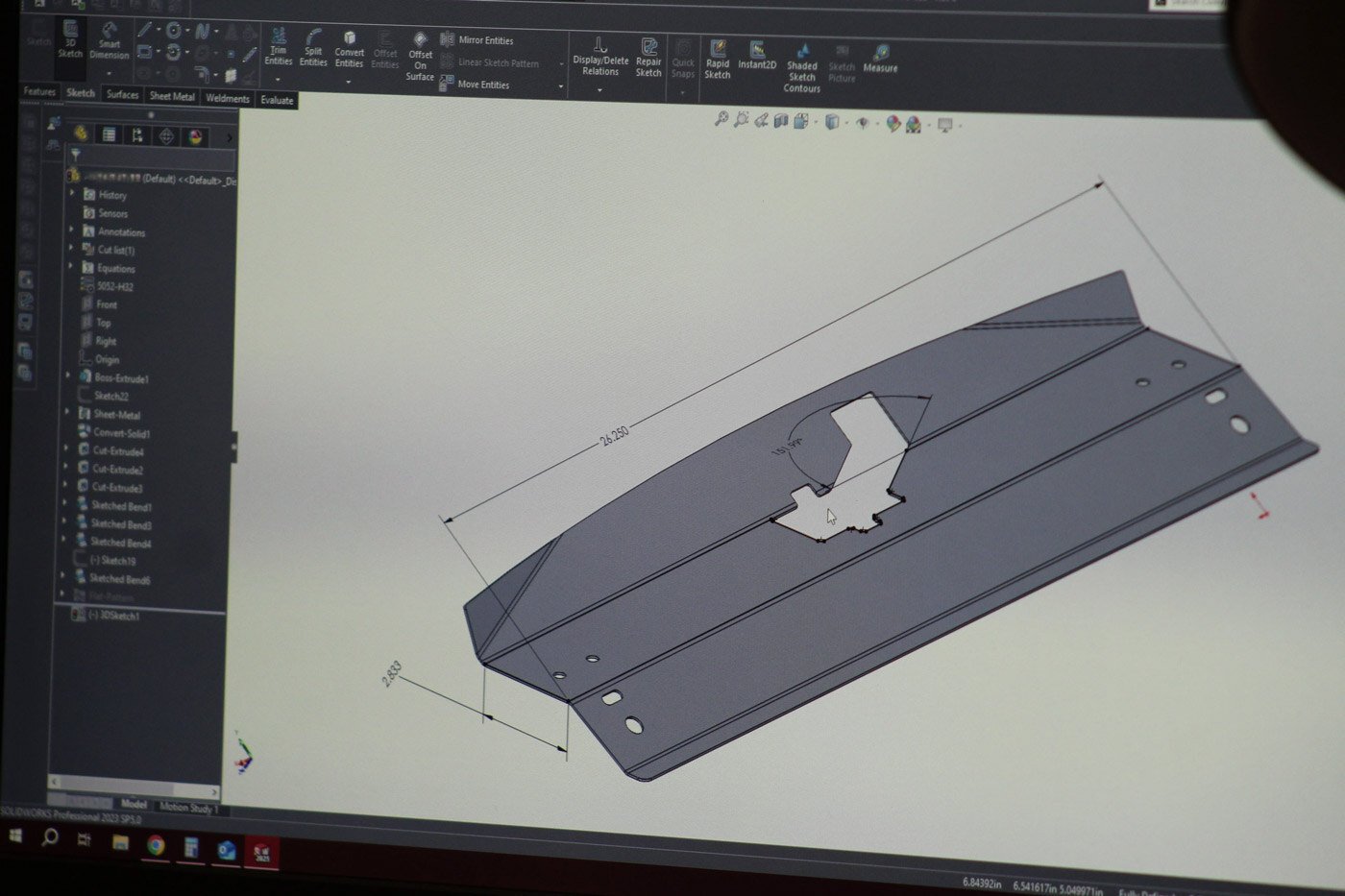

Our on-site CAD, reverse engineering, and prototyping services provide end-to-end support, helping you develop and refine your product for optimal performance.

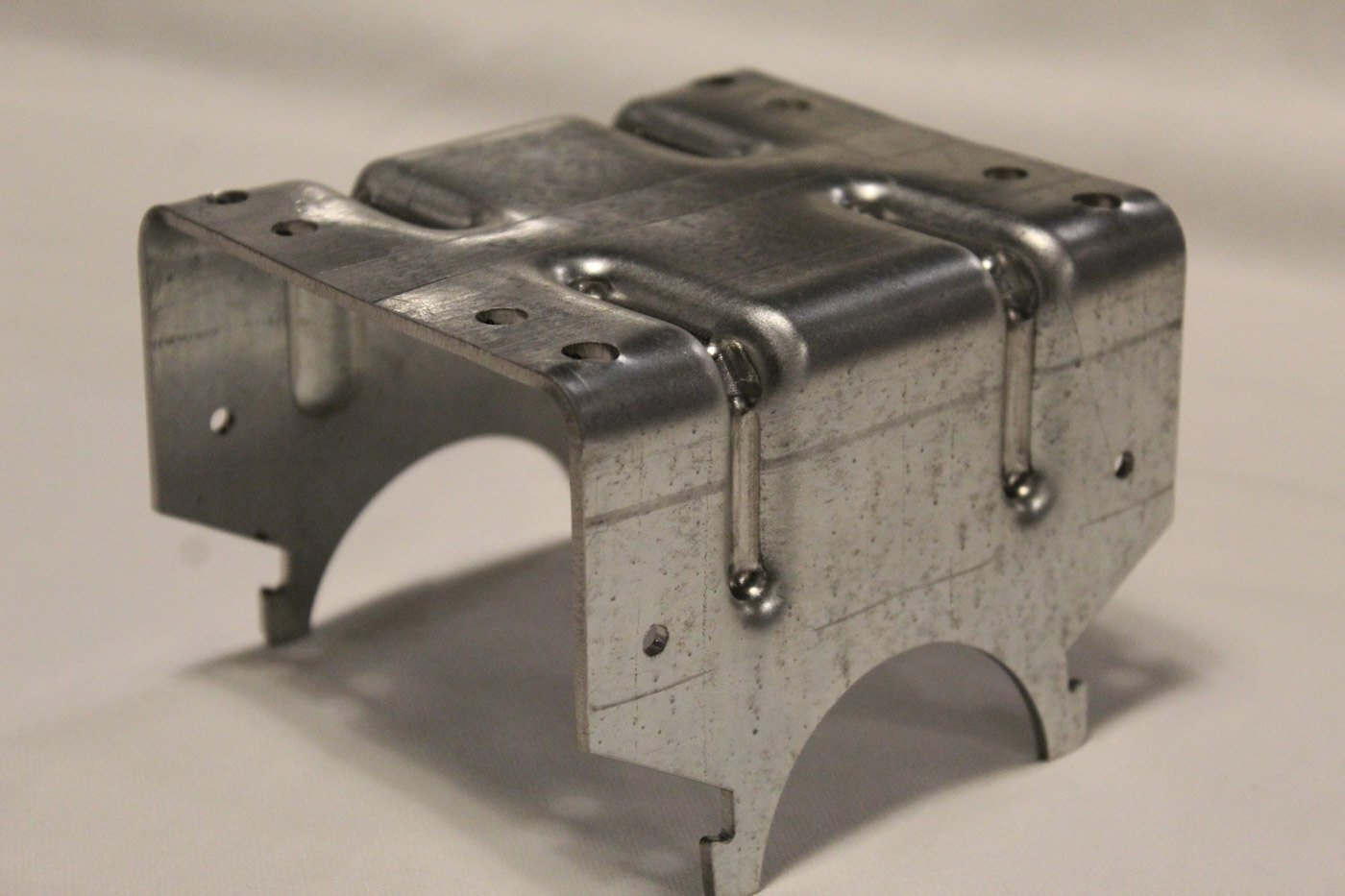

We offer complete assembly and sub-assembly services, including precise fastener installation, to streamline production and ensure your parts are ready for final use.

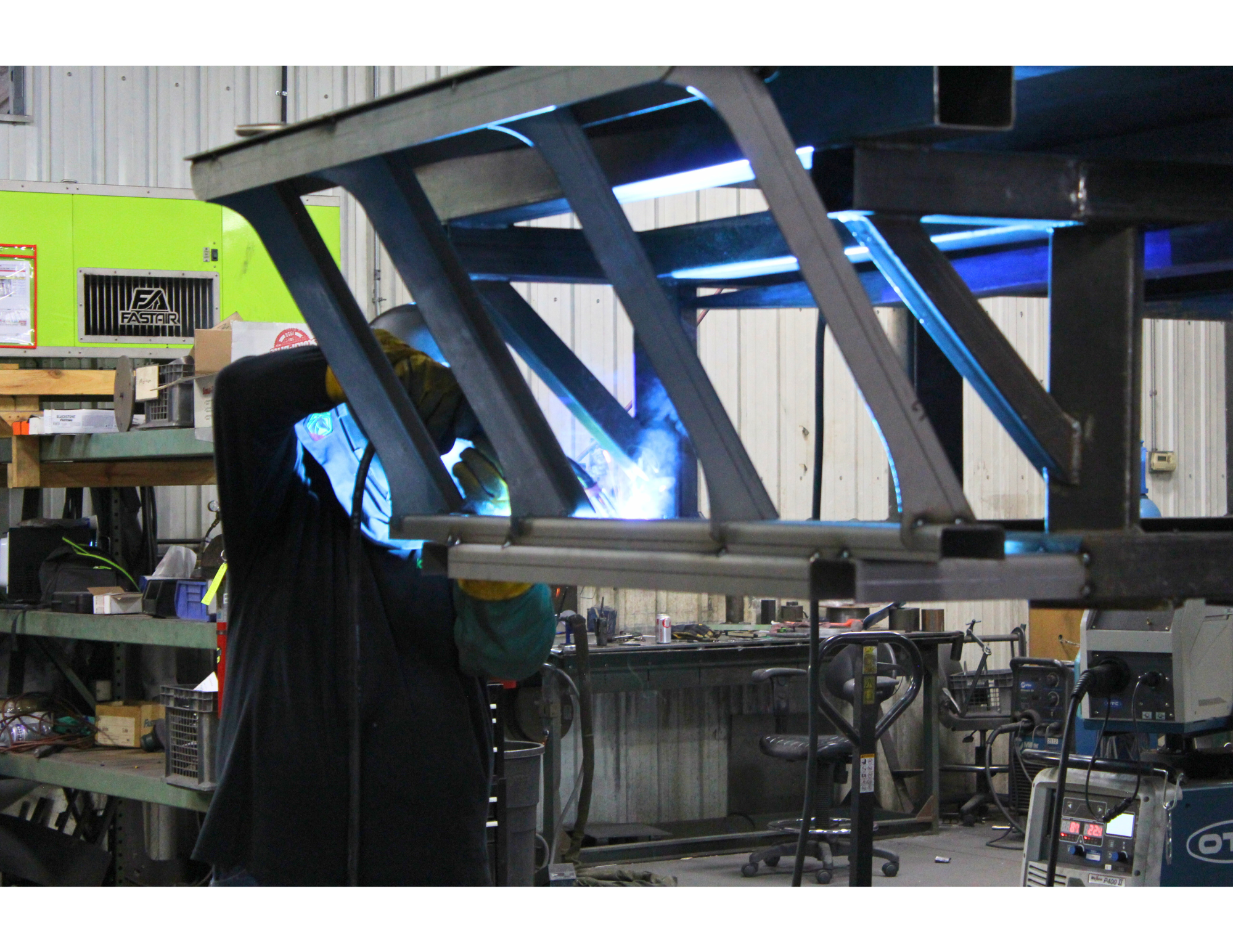

With expertise in bending, rolling, and seam-welding, our metal forming capabilities create complex shapes with precision and strength for a variety of applications.

Our in-house polishing, deburring, and edge-finishing services ensure durable and visually appealing parts, providing a professional finish. We also offer powder-coating for added protection and aesthetics.

We specialize in precision metal punching, stamping, and beading, delivering detailed and consistent results for high-volume and custom projects alike.

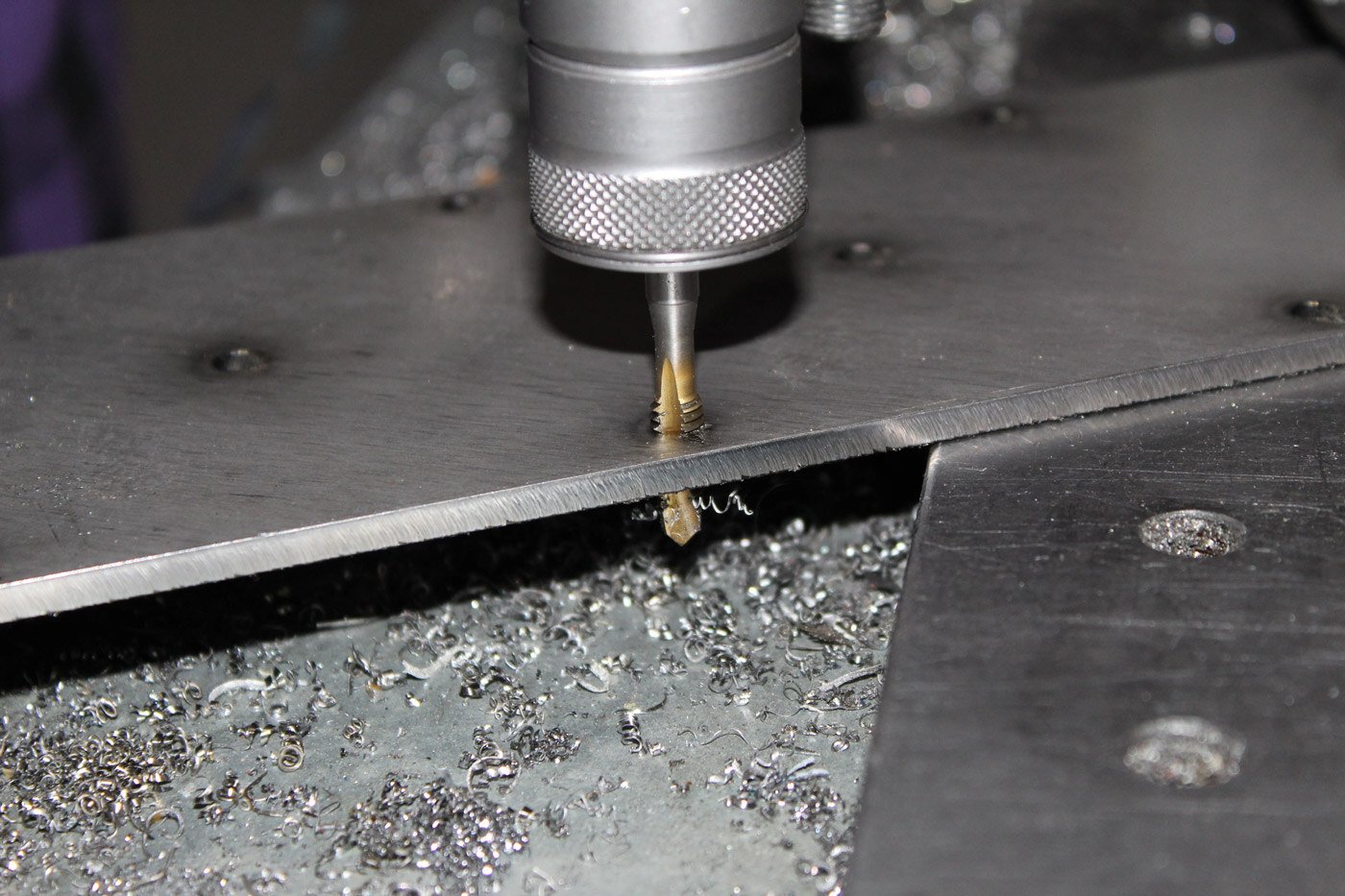

Our tapping and threading services deliver accurate, high-quality threads to ensure compatibility and ease of assembly across your components.

Ready to learn more? Connect with us and let’s discuss your needs.

At KRYTON Metals, our value-add services are tailored to enhance your project’s success.

Comprehensive Tooling & Welding

Streamline your production with our all-inclusive tooling and machining capabilities, from initial cuts to final touches.

Advanced Technologies for Optimal Results

Our utilization of automated CNC systems and IoT-enabled equipment ensures precision and efficiency for your project.

Expertise Across Multiple Industries

No matter your industry—whether it’s aerospace, medical, food processing, or industrial manufacturing—our team’s expertise spans a wide range of sectors.

Lorem Ipsum

Ready to learn more? Connect with us and let’s discuss your needs.

Value-add services in metal fabrication include additional processes such as engineering, welding, finishing, assembly, and more. These go beyond basic fabrication to provide a fully finished, ready-to-use product.

KRYTON Metals works with a variety of materials, including aluminum, stainless steel, carbon steel, copper, and brass. Each material is handled with precision to meet the specific needs of your project.

Welding is a key part of our value-add services, and includes GMAW (MIG), GTAW (TIG), spot and automated seam welding. We work with various metals and thicknesses to deliver strong, reliable welds that meet industry standards.

We offer a range of finishing options, including powder-coating, in-house polishing, and other processes designed to enhance both the durability and appearance of your metal parts.

Our value-add services cater to multiple industries, including aerospace, automotive, medical, energy, and more. We deliver tailored solutions that meet the stringent requirements of each sector.

To start a project or get a quote, contact us through our website or by phone. Provide details about your project, including material specifications, dimensions, and any special requirements.

Reach Out