Guide

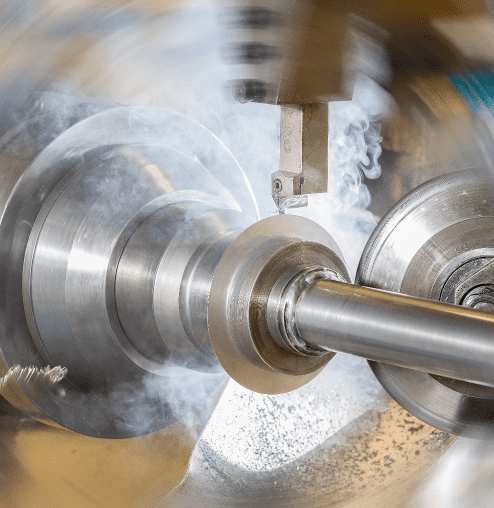

WHAT IS METAL SPINNING?

Metal spinning, also known as spin forming, is a metalworking process where a disc of metal is rotated at high speeds and formed into an axially-symmetric part using spin tools. Picture the art of pottery sculpting, but envision it in a horizontal plane, and instead of molding clay, we’re shaping metal! Metal spinning is used in various industries to produce a wide range of products—anything from architectural pieces, speciality lighting, and decorative household goods to cookware, gas cylinders, and much more. For cones and domes, specifically, the roller tool exerts force onto the sheet metal while spinning, pushing the metal onto the mandrel and creating a seamless, symmetrical, and smooth product. This manufacturing process is particularly effective for creating rounded or conical shapes.

What Raw Materials Can Be Used?

Typically, the most common types of metals that are being spun in our shop are aluminum, stainless steel, and mild steel. Without getting into the deep specifics, different metals have different properties, so the preferred metal for cones and domes depends on the application of the part. Mild steel tends to be more cost-effective, but it is prone to rust under certain weather conditions. Aluminum won’t rust, but it is a much softer metal when compared with stainless steel.

WHAT PRODUCTS CAN BE MADE?

There are many examples of products that are made from cylindrical and ring-like shaped metal spinning. Some of which many of us see and walk past every day, such as cookware, musical instruments, lighting fixtures, ventilation ducting reducers, hose reels, Salt Spreaders, Fire Pit Rings Lids/Garbage Lids, Hoppers/Funnels, Lampshades, Architectural Lighting Fixtures.

What Sizes Can Be Achieved?

This group about cylindrical and ring-like shapes have almost identical spinning capabilities as the first group about the conical and dome shapes. Of course, the shapes and geometries are different, but the biggest OD being spun and material thickness limitations are the same as the conical and dome-shaped sections. Our maximum blank diameter for spinning is still 102”.

Instead of repeating the capabilities, here are some differences:

Cylinder Capabilities

Cylinders can be rolled or spun—main criteria are:

Is it a large diameter cylinder? If so, it will most likely be rolled.

If it is rolled, will the customer be okay with a visible weld seam that is used to join the rolled metal into a cylinder? If not, then spinning may be the next best choice.

If it’s a small diameter cylinder, it may be able to be spun.

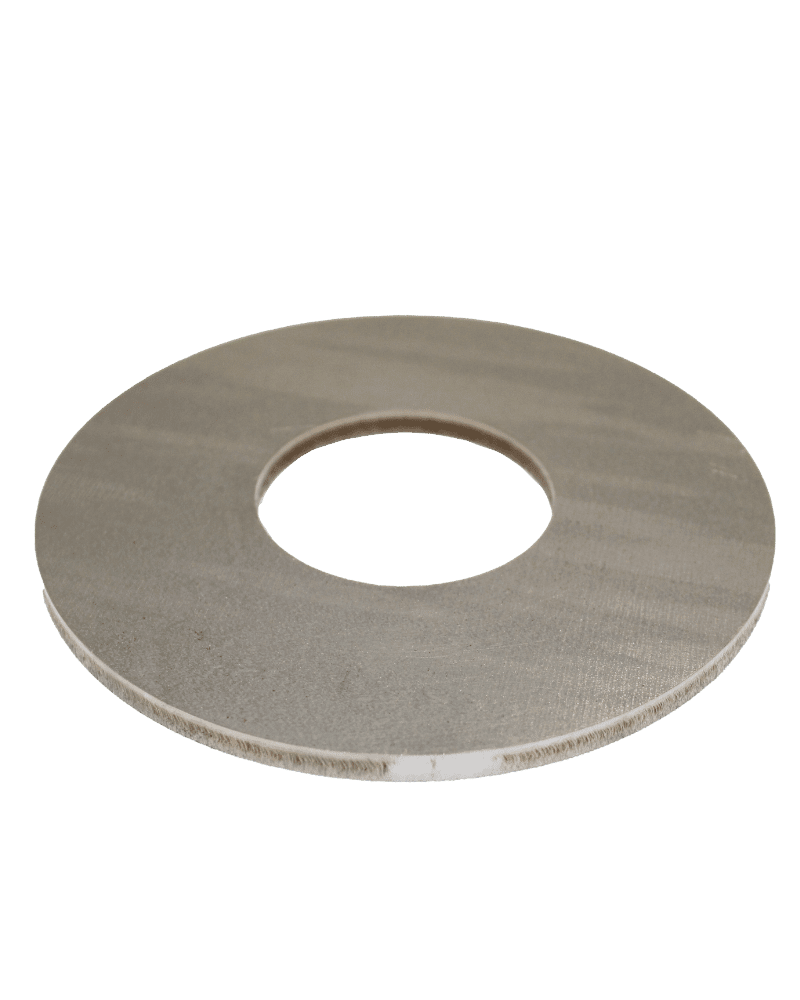

Disc Capabilities

Discs are a bit misleading, because discs are laser cut instead of being spun. Because of the ring-like shape section, discs happen to fall into this category.

Since discs are laser cut, the maximum overall diameter for the disc depends on the laser capabilities.

In our case, the biggest area that our automated laser can cut is 159” x 81”. That means our largest disc size that can be cut is just about 81” in diameter.

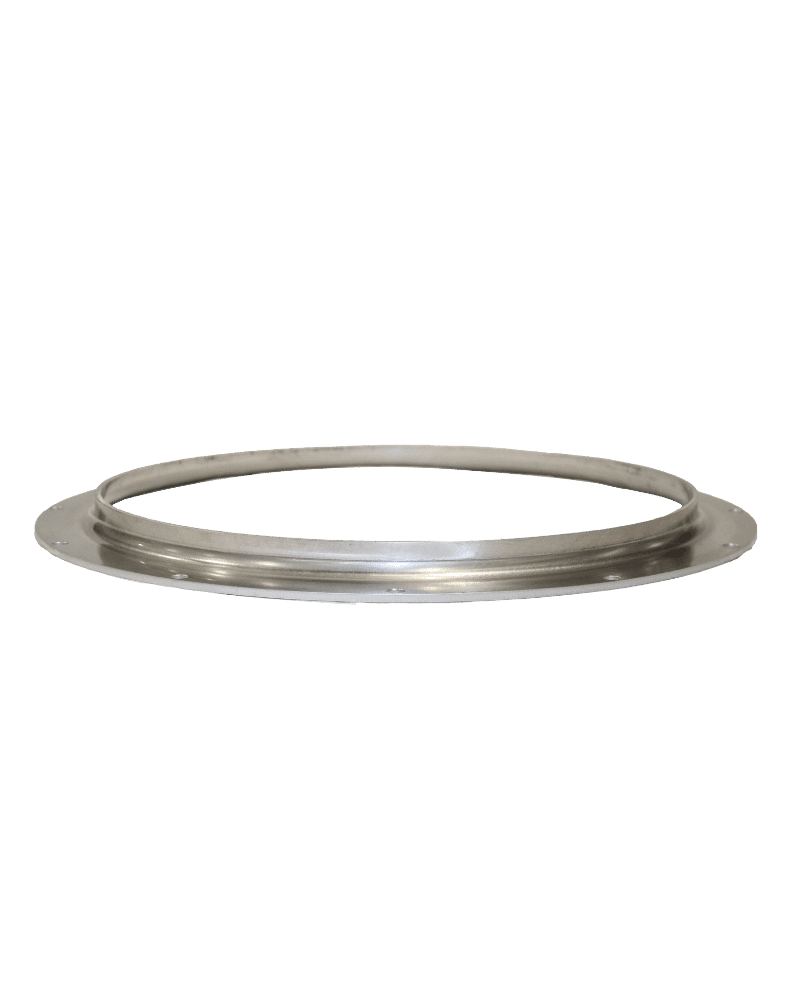

Flange Capabilities

Flange shapes generally get an in-spin, which consists of a flat blank being cut, and instead of a smaller hole used for metal spinning, there will be a large hole where material around it will get pushed out by the tooling to form a part that’s usually flat on the bottom and usually has a straight “wall” or a curved geometry on the spun surface.

The flat portion of the flange parts may get other operations done as usual (i.e. forming/bending).

Bellmouth/Reducers Capabilities

The shape contains similarities when compared to a shape of a cone-like part. The capabilities of a bellmouth/reducer-shaped part will generally have the same capabilities as the parts from group o

Thickness

Here’s a chart of KRYTON’s metal spinning material thickness capability:

|

Mild Steel |

⅜” (0.375”) |

|

Stainless Steel |

3/16” (0.1875”) or 7 Gauge |

|

Aluminum |

½” (0.5”) – Must Be O-Tempered |

Kryton Metals

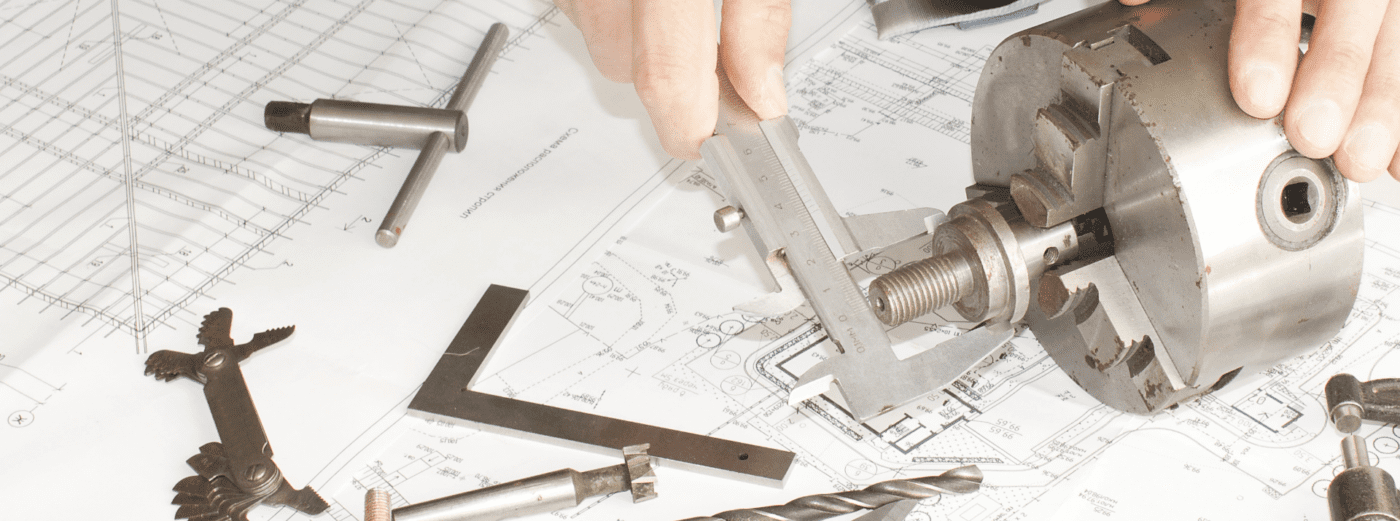

Quality Control

Our product quality control process is meticulous and thorough, ensuring the highest standard at every stage of production. Every new part undergoes a quality assurance inspection before every operation.

For instance, after a flat blank is laser cut, it is immediately checked by our QC team. The same checks are applied after metal spinning the flat blank, trimming, 3D laser cutting, and any other processes that may be applied. This diligent process guarantees that every part meets the customer’s and our exacting standards before it leaves our facility.

Finally, before a part is shipped to the customer, it undergoes one last comprehensive check, ensuring that what reaches our customer is nothing short of perfection.

Guide

How Does Pricing Work?

Generally, the pricing process stays the same as it would for the first group, but of course, there is the difference between rolling and spinning.

Rolling will get a seam-weld step (most of the time) to join the two ends of the rolled blank together—with this being two steps, it will add onto the pricing. Instead of rolling, metal spinning is usually just one process—note that most of the time, spun metal will get a trim step, whether it’s trimming in a cell or on our 5-axis laser, which is another process.

However, metal spinning, most often, requires high tooling costs which may not be the most cost-effective route. To add onto the costs, metal spinning usually starts with circular flat blanks which take up more space per sheet than a rectangular flat blank for rolling will.

Quick example.

A rolled cylinder with a diameter of 12” and a height of 6” will have a flat blank size of around 37.7” x 6”. A spun cylinder will have a flat blank of around 17” in diameter. When you look at the area of the two, they both have roughly the same area, but when you look at how many can fit on a 60” x 120” sheet size, you can fit 21 circular flat blanks in for metal spinning, or you can fit 24 rolled flat blanks in.

While the difference may not be much, in some cases of higher quantities, it may be more cost-effective to pick the rolled cylinder route, but of course, that’s just a small example. However, in some cases, some blanks are rolled, seam-welded, and then spun, which isn’t ideal most of the time, since the weld seam can be problematic while spin forming.

Wrapping Up

Let’s shape the future together!

If you’re interested in learning more about our services, wanting a deeper understanding of our capabilities, or simply obtaining a quote for your project, don’t hesitate to contact our KRYTON team. We’re always ready to turn your ideas into reality with our state-of-the-art metal spinning techniques.