Materials

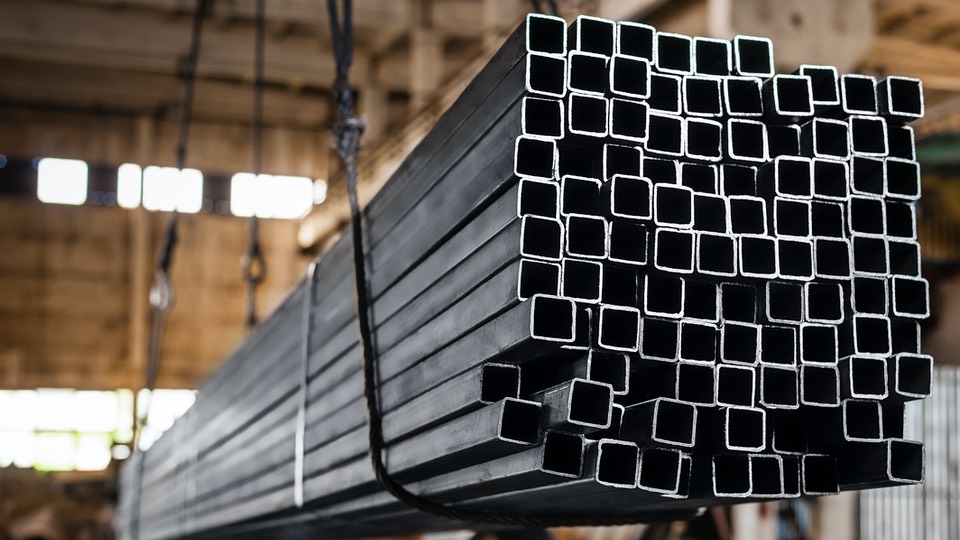

Carbon Steel in Metal Spinning

Carbon steel is prized for its superior strength, rigidity, and versatility. Its composition, primarily iron and carbon, allows it to produce exceptionally durable parts that outperform many other materials in terms of structural integrity. The varying carbon content offers a range of properties, from enhanced toughness to increased hardness, making it an ideal choice for applications that demand reliability and resilience under high stress and wear.

Request a QuoteLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididtat non proident.

Made in the USA since 1981.

Why Choose Carbon Steel?

Carbon steel, an alloy primarily composed of iron and carbon, is favored for its strength and durability. The carbon content in the steel can range from 0.12% to 2%, directly influencing the material's characteristics. Unlike other steel alloys, carbon steel does not require the inclusion of elements like chromium or nickel, making it more cost-effective while still providing high performance in demanding environments.

Key Characteristics of Carbon Steel

Carbon steel stands out in metal spinning due to several critical properties:

Exceptional Strength

The higher the carbon content, the stronger and more rigid the steel becomes, making it suitable for heavy-duty applications.

Cost-Effectiveness

Carbon steel is often more affordable than other steel alloys, providing a cost-effective solution without compromising on durability.

High Durability

Known for its toughness, carbon steel is highly resistant to wear and tear, making it ideal for long-term use.

Versatility in Grades

Carbon steel is available in various grades—low, medium, and high-carbon—each offering different levels of strength, ductility, and weldability to suit specific needs.

Ready to learn more? Connect with us and let’s discuss your needs.

Lorem Ipsum

Lorem Ipsum

Ready to learn more? Connect with us and let’s discuss your needs.

Materials

Applications of Carbon Steel

Carbon steel’s robustness and versatility make it a prime material for a variety of industries. At KRYTON, we produce carbon steel components for:

- Agricultural Equipment: Carbon steel is used in plow blades, discs, and other farm tools that require extreme durability.

- Energy Sector: Ideal for components such as piping, valves, and fittings, where strength and resistance to high pressure are crucial.

- Construction: Used in structural elements like beams and supports, carbon steel provides the necessary strength for building infrastructure.

- Industrial Machinery: Carbon steel is perfect for gears, shafts, and other machine parts that endure significant stress.

- Automotive Industry: Frequently used in the manufacture of automotive parts like axles, crankshafts, and chassis components due to its toughness and longevity.

KRYTON’s Carbon Steel Metal Spinning

Ready to request a quote?

We bring our extensive experience to every carbon steel project, crafting strong, uniform parts that meet your specific requirements. Whether you need industrial-strength components or precision-engineered parts, our expertise in metal spinning with carbon steel guarantees products that deliver on quality and performance, all within your budget.